What is an industrial pesticide sprayer?

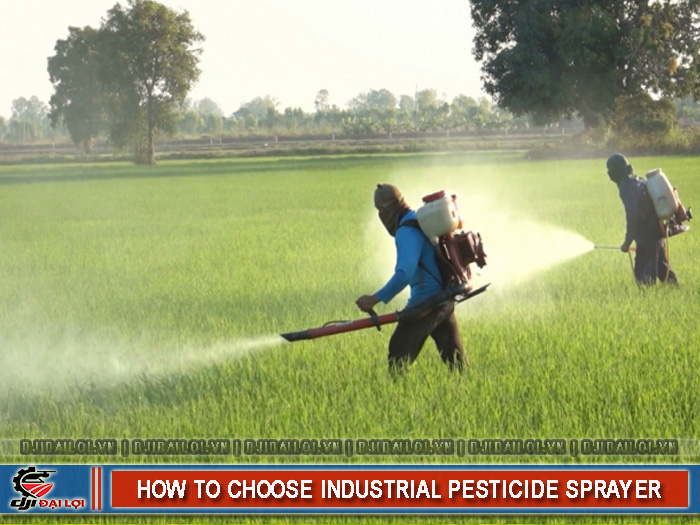

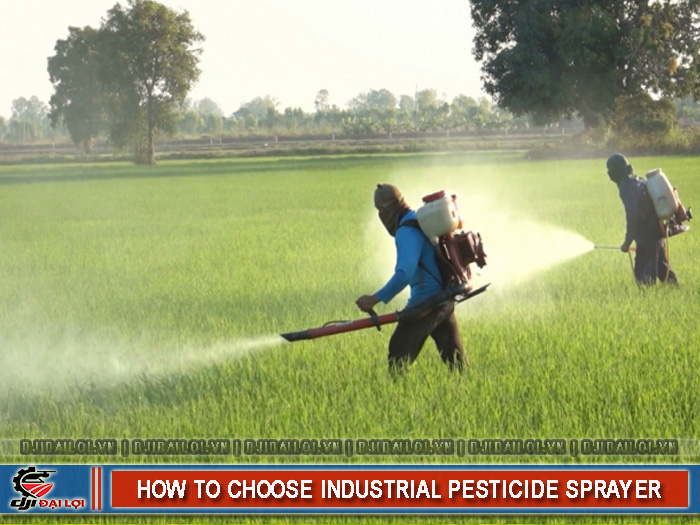

An industrial pesticide sprayer is a specialized agricultural device used for large-scale cultivation (orchards ≥ 1 ha, farms, cooperatives, etc.) to spray plant-protection chemicals such as pesticides, fungicides, or foliar fertilizers. It delivers much higher performance than handheld or household sprayers.

Key features of industrial pesticide sprayers

- High power output: from 2 – 5 HP or more for strong, continuous spraying

- Large tank capacity: 25 – 50 liters or higher to reduce refilling frequency

- High spray pressure: ensures even coating from root to canopy, even on tall trees

- Engine types: typically gasoline or electric, some semi- or fully automated

- Support features: backpack, trolley, boom sprayer, mist type, or drone. Modern spraying drones from DJI Đại Lợi now offer automated control to reduce direct chemical exposure and improve coverage accuracy.

When should you use an industrial sprayer?

- Large-area fruit orchards, rubber, or coffee farms (≥ 1 – 2 ha)

- Farms needing simultaneous pest control in a short time

- When you want to cut labor costs and improve accuracy

- When spraying tall, dense, or hard-to-reach crops. For farms over 5 ha, many producers also use agricultural drones to boost speed and coverage.

Benefits of using an industrial pesticide sprayer

- Time-saving: 2–3× faster than manual spraying

- Labor-saving: one operator can replace three to four workers

- Higher pest-control efficiency: fine mist, even coverage, less runoff

- Reduced chemical exposure thanks to long nozzles or remote control

For commercial-scale agriculture, an industrial sprayer is an indispensable investment to improve productivity while reducing dependence on manual labor.

Why choosing the right industrial sprayer matters

In large-scale agriculture, spraying efficiency directly affects crop yield and labor costs. An industrial sprayer saves time and ensures chemicals are evenly distributed, minimizing waste and environmental harm. Choosing an undersized or unsuitable machine can make spraying ineffective and even damage crops.

A 2023 report by the Ministry of Agriculture found that over 38% of farms used mismatched equipment, doubling or tripling maintenance costs annually — emphasizing the importance of selecting the right sprayer for your farm size and crop type.

Proper selection also:

- Improves coverage and reduces localized fungal outbreaks

- Cuts labor costs during peak seasons

- Minimizes chemical exposure via automation

- Extends crop lifespan and boosts yield

A wrong purchase can waste millions of VND each season — so smart investment from the start is key.

Factors to consider before buying

- Farm size and crop type – A 1-ha orchard needs a different setup than a 5-ha coffee farm or rice field. Hilly or segmented terrain favors lightweight, mobile sprayers.

- Power source – Gasoline models suit remote areas; electric ones are quieter for accessible farms.

- Usage frequency – Heavy-use farms (2 + times/week) should choose durable, high-pressure machines with readily available spare parts.

- Budget – Prices range from ₫5 – 50 million depending on power and brand.

- Maintenance and parts – Prefer brands with local service centers and spare parts.

- Safety standards – Ensure the sprayer meets labor-safety and chemical-containment requirements, especially in cooperatives or large farms.

Criteria for choosing a high-power industrial sprayer

1. Assess area and terrain

- Flat fields → trolley or boom sprayers.

- Hilly terrain → backpack or wheel-assist sprayers.

→ For ≥ 2 ha: tank ≥ 25 L, power ≥ 1.5 HP, pressure ≥ 20 bar.

2. Choose the right engine type and power

- Gasoline engine: powerful, mobile, ideal for remote areas.

- Electric engine: quieter, cleaner, low-maintenance but power-dependent.

→ 1.5–2.5 HP for < 5 ha ; ≥ 3 HP for large farms or boom sprayers.

3. Check spray flow rate and pressure

- Flow rate ≥ 6 L/min; pressure 20–40 bar.

→ For durian, mango, or tall trees, choose high-pressure models (range ≥ 8 m).

4. Tank capacity and build material

- 16–25 L → small/hilly farms.

- 30–50 L → large flat farms.

- Inox = durable; HDPE plastic = light, chemical-resistant.

5. Machine configuration

- Backpack → agile mobility.

- Trolley → less fatigue, needs smooth paths.

- Boom sprayer → tractor or motorbike-mounted for large-scale farms.

6. After-sales support

- Prefer brands with local dealers, available spare parts, and clear warranty terms.

Common mistakes when choosing industrial sprayers

- Underpowered machines → overwork and rapid wear (e.g., 1 HP for 5 ha).

- Buying solely on price → poor-quality, unbranded units.

- Ignoring terrain conditions → wrong type for the landscape.

- Unavailable spare parts → long downtime during spraying season.

- Neglecting safety → low-grade filters or leaky nozzles increase risk.

5 recommended high-power industrial sprayers

Honda WJR 2525T1 – Japan

- Tank 25 L • 2-stroke gas engine • Range ≥ 10 m

- Durable, fuel-efficient, easy-to-find parts

- Ideal for 1 – 3 ha orchards • ~ ₫8 million

Lavor Michigan 1211LP – Italy

- High-pressure industrial sprayer • Adjustable pressure

- Dual use: spraying + cleaning

- For farms ≥ 5 ha • ~ ₫18.5 million

STIHL SR 5600 – Germany

- 3.5 HP • 14 L tank • Range 11–13 m

- Lightweight backpack, durable • ~ ₫6.5 million

Z-Kubota GX35 – Thailand

- 4-stroke GX35 engine • 50 L tank • Large-wheel trolley

- Stable, easy handling • ~ ₫8.85 million

Lavor Arizona 1311LP – Italy

- High-power, multipurpose industrial model

- Sprays + cleans barns/machinery

- Ideal for mixed farms • ~ ₫16.5 million

→ Choose brands with local service centers and accessible parts; avoid unbranded imports.

Should you choose a gasoline or electric industrial sprayer?

Gasoline sprayer

- Pros: independent of grid power, powerful, suited for wide or remote areas.

- Cons: noisy, higher fuel cost, periodic maintenance, exhaust emissions.

→ Best for 3 – 10 ha farms, hilly or outdoor conditions.

Electric sprayer

- Pros: quiet, eco-friendly, easy to operate, low long-term cost.

- Cons: relies on electricity or battery; lower power output.

→ Best for greenhouses, vegetable gardens, or powered areas.

Summary: For mobility and rugged terrain → gasoline; for quiet, cost-efficient use → electric.

Conclusion

Selecting the right industrial pesticide sprayer enhances productivity, reduces labor, and ensures crop safety and longevity. Carefully assess power, configuration, engine type, and field conditions before investing. Reliable after-sales service is crucial for long-term performance.

FAQs about industrial pesticide sprayers

Do I need a permit to use spraying drones?

Yes. Under Decree 36/2008/NĐ-CP, agricultural drone operations require flight approval from the General Staff with defined zones and purposes.

How do I know if the sprayer suits my pesticide?

Check spray pressure, tank material, and nozzle chemical resistance; follow the pesticide’s usage guide for industrial or drone compatibility.

Which sprayer suits hilly terrain?

Use a lightweight 16–25 L gasoline backpack sprayer with ≥ 25 bar pressure; optional wheels or handles ease uphill work.

What type should be avoided in wet or low areas?

Avoid electric or small-wheeled models; choose waterproof, sealed systems to prevent short circuits.

How long is the warranty?

Typically 6 – 12 months depending on brand; prefer those with local service centers and readily available engine parts.