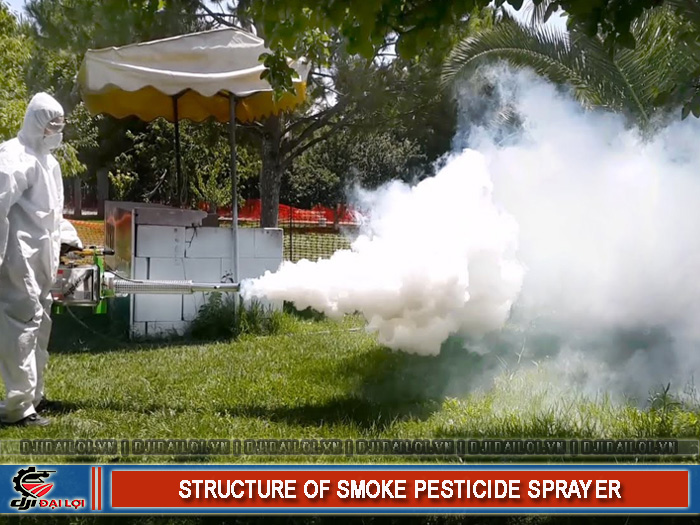

Over the past few years, thermal fog sprayers have become widely used in agriculture, pest control, and large-scale sanitation. But what exactly are they, and why use fog instead of liquid spray or mist?

A thermal fog sprayer is a machine that uses high temperature to vaporize a liquid solution into dense fog or smoke. The fog particles are then dispersed into the air to kill insects, pests, or harmful microorganisms. This device works based on thermal decomposition and pressure, allowing the particles to spread widely and cling longer to plant surfaces or treated areas.

Unlike mist or pressure sprayers, thermal foggers can cover large areas using minimal chemical solution, as they produce ultra-fine droplets (typically under 50 microns). They are ideal for spraying in open environments or for deep penetration into plant canopies and narrow spaces such as rice fields, fruit orchards, greenhouses, warehouses, and livestock barns.

Among the most common types is the thermal fogger, used for mosquito and insect control in cities, hospitals, schools, and households. These machines can work with various specialized solutions - pesticides, disinfectants, insecticides, or antibacterial agents. Depending on the model, some sprayers include adjustable fog flow, droplet size selection, or compatibility with multiple fuel types.

To understand how efficiently these machines work, we must first look at their internal structure. Each component plays a distinct yet interconnected role, ensuring that fog generation and dispersion remain stable, safe, and effective.

This tank holds the liquid solution, typically made of stainless steel or aluminum alloy for corrosion and heat resistance. Capacity ranges from 5–20 liters, depending on the model. Some tanks include anti-spill valves and safety-lock caps for user protection.

The core of the sprayer is its combustion engine (usually gasoline-powered or spark-ignition). The combustion chamber heats the chemical delivery tube, vaporizing the liquid into fog. The temperature in this section can reach 300°C–600°C.

A manual or automatic pump generates pressure to push the liquid from the tank into the combustion tube. These tubes are made of heat- and chemical-resistant materials to maintain pressure and distribute the solution evenly during operation.

The nozzle is usually made of heat-resistant metal or a widened diffuser design that prevents clogging and ensures fast, uniform fog dispersion. Some machines feature Venturi nozzles to increase airflow speed and produce finer fog particles.

This unit regulates the spray flow, duration, and in advanced models, the spray angle. High-end sprayers may have automatic shut-off valves, emergency switches, and temperature sensors to prevent overheating or engine overload.

Thermal fog sprayers vary by working principle, power source, and intended use. Understanding these differences helps users choose the right model for maximum performance and cost efficiency.

When purchasing a thermal fog pesticide sprayer, it’s crucial to choose a reputable supplier to ensure machine safety, warranty, and genuine spare parts. Among the trusted distributors in Vietnam, Đại Lợi stands out for offering a full range of agricultural sprayers and drone-based spraying equipment, including thermal foggers, ULV cold foggers, and high-pressure sprayers. With professional technical support, operator training, and nationwide after-sales service, Đại Lợi has become a reliable partner for farmers and agricultural cooperatives seeking efficient pest-control solutions.

Fog is just a carrier; excess smoke wastes chemicals and can harm crops.

Each machine has compatibility limits. Using the wrong solution may clog the nozzle or produce toxic gases.

Fog particles can still contain chemicals; always wear goggles, gloves, and a mask.

Low-quality machines may leak, overheat, or even explode due to poor combustion chambers or seals.

|

Criteria |

Thermal fogger |

Cold fogger (ULV) |

High-pressure sprayer |

|---|---|---|---|

|

Droplet size |

5–30 microns |

10–50 microns |

50–100 microns |

|

Working principle |

Heat vaporization |

Motorized atomization |

Pump pressure |

|

Diffusion power |

Very strong, wide coverage |

Good for indoor use |

Limited in open areas |

|

Chemical consumption |

30–50% lower |

Moderate |

High |

|

Safety level |

Requires heat control |

High |

Safe but leaves moisture |

|

Typical uses |

Agriculture, mosquito control, outdoor disinfection |

Offices, warehouses, greenhouses |

Small gardens, livestock |

|

Approx. price (VND) |

5–20 million |

3–10 million |

2–8 million |

|

Mobility |

Medium (fuel required) |

High |

High |

When to choose which:

Understanding the structure and operation of thermal fog sprayers helps ensure proper selection, safer usage, and higher efficiency. From combustion design to application principles, these machines are vital in modern agriculture and disease control.

In the future, combining fogging technology with automation, drones, and AI navigation could significantly advance plant protection and agricultural efficiency.

Depending on the formula and environment, 3–7 days. Sunlight or rain may shorten this period.

Clean the combustion chamber and nozzle after each use; inspect spark plugs, valves, and tubing every 30–50 hours.

Yes, but only heat-resistant formulations. Use machines with adjustable or low-heat settings.

Follow label dilution rates and adjust slightly based on area size, canopy density, and wind speed.

Weak fog output, large droplets, strange noises, burnt smell, or oil leakage - all indicate clogging or engine failure.